Our Solutions: Active Vacuum Belt Filter

Q-Filter®

Q-Filter® is the solution for the filtration of valuable fluids like aqueous cleaners and machine coolants. Filtration down to 5µm, even to 1µm is possible!

Its unique, intelligent control system controls the filtration process and the pressure drop over the cloth. This prevents compression of the cloth and promotes the formation of a filter cake; you remove more dirt with less filter cloth.

The special transport system ensures a trouble-free installation and transportation of the filter cloth.

The perfect sealing and the controlled formation of a filter cake results in a much finer filtration. This way you remove more and finer dirt and keep your medium even cleaner.

- Economical: Low operational cost and long medium lifetime.

- Effective: Low filter consumption through optimal control of the filtration process.

- Efficient: You get a much finer filtration due to perfect sealing and process control.

- Energy efficient: You only use less than half the energy.

- Compact: You need only half the floor space.

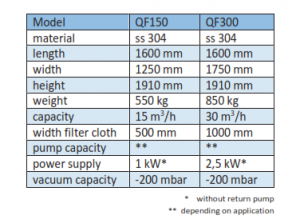

- Active Vacuum Belt Filter

- Vacuum -200mbar

- Capacity 15 to 30 m3/h

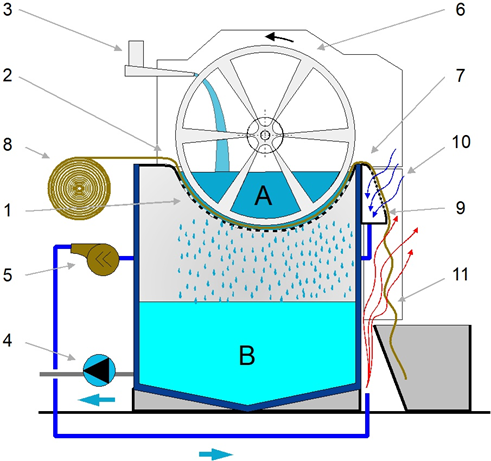

HOW Q-FILTER® WORKS

The two chambers, A (dirty chamber) and B (clean chamber), positioned above each other, are separated by the filter cloth (2) which is supported by the curved sieve plate (1).

The polluted medium flows through the inlet (3) into chamber A and through the filter cloth into chamber B, where pump (4) pumps off the clean fluid.

Dirt accumulates on the filter cloth and forms a cake, which causes the level in A to rise. If a previously set level is reached, vacuum pump (5) kicks in and creates underpressure in chamber B, causing the medium to be sucked through the cloth and preventing the level in A from rising any further.

As the filter cake on the cloth grows, the underpressure in chamber B is further increased until a set maximum. At this point, the cloth is forwarded over a short distance by turning of the wheels (6). Used cloth (7) comes out at the right while the fresh cloth is pulled from the roll (8), into the device. Then the cycle starts over again.

The used wet cloth comes onto the drainage box (9) where it is dried. The vacuum pump (5) pulls in air (10) through the wet cloth and the drainage box, pulling fluid out of the cloth. The fluid ends up in chamber B. To further dry the cloth, the exhaust air from the vacuum pump is blown from the bottom up along the free hanging section (11) of the cloth.

For more information on the one-of-a-kind, Q-FILTER® contact K Factor Filter at 1-855-593-7301.

More Media Filteration Solutions

The GT-MAG