Our Solutions: Magnetic Separator

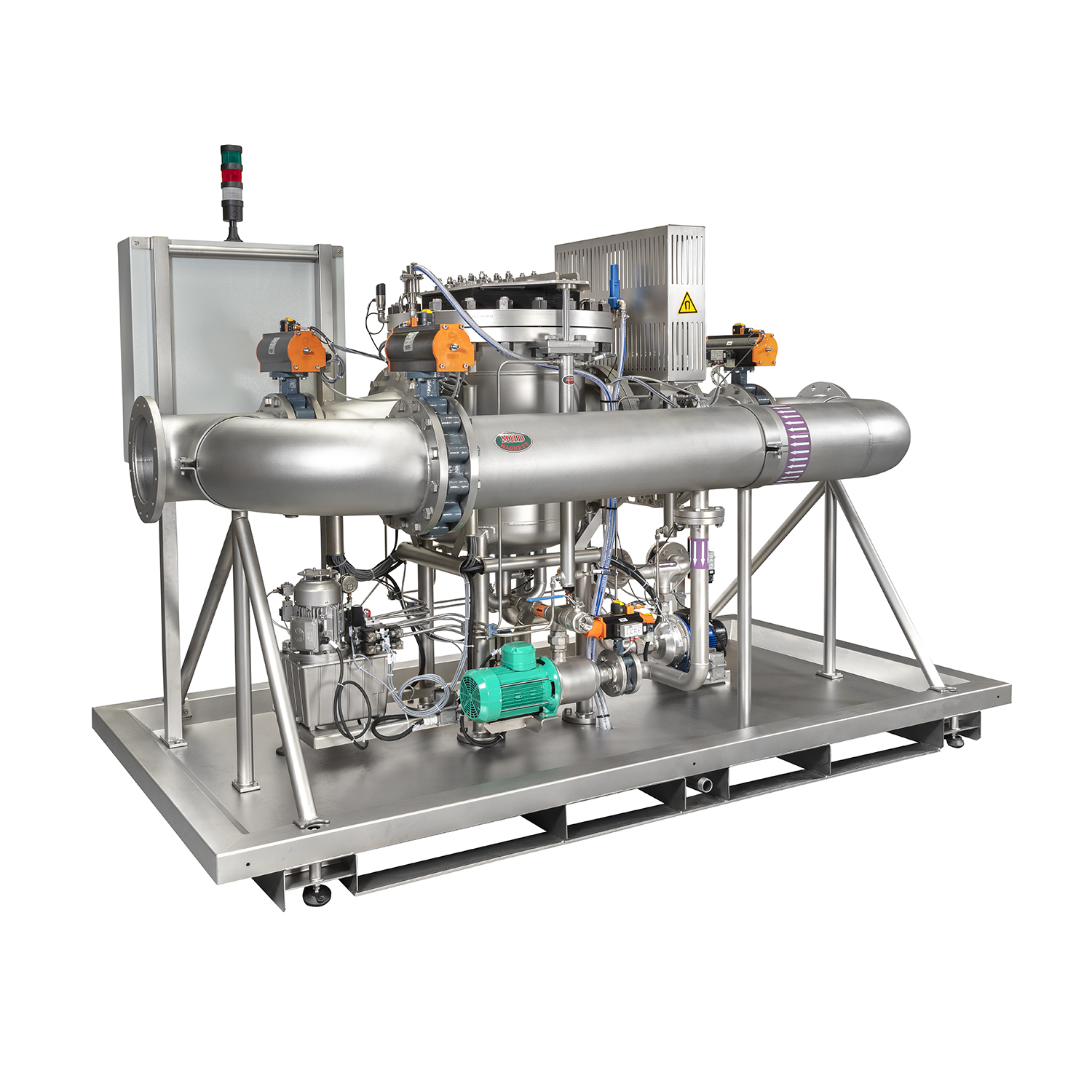

PAC-MAG

The PACMAN first stage inline magnetic separator is designed to effectively remove micron-size ferritic particles from among other degreasing fluids. The main principle of the functioning of the PACMAN is a tailored combination of magnetic engineering and fluid dynamics:

- The permanent magnetic flux density of 1.28 Tesla (12800 Gauss) and a surface area up to 2.7 m2.

- Decelerated longitudinal or transverse fluid flow of > 0.4 m/sec over the magnetic elements.

The PACMAN can be delivered with an on-board industrial PLC for stand-alone operation, integrated with the ROTOMAG and/or integrated with the factory control system. Depending on the rate of pollution the PACMAN is automatically drained and rinsed at a configurable frequency by the fully integrated spray cleaning system. The maximum load is 30 kg (dry weight) per m2 magnetic surface. Fe particles are trapped on the outer surface of the stainless steel magnetic elements. In the matrix of the aggregates, numerous non-magnetic particles (i.e. sealer and fibers) can be found.

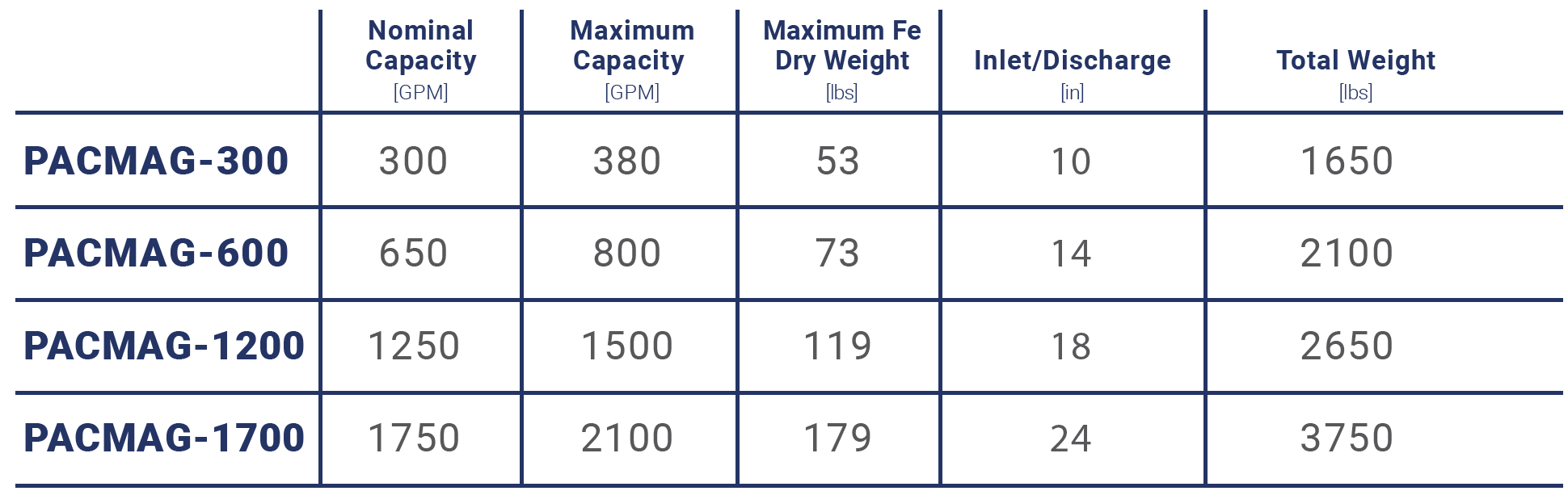

- FLOW RATE up to 2100 GPM

- PANEL: Allen Bradley with HMI

- BODY Stainless Steel 304

- SEPARATION EFFICIENCY up to 2 mg/L Fe dry weight

- HYDRAULIC MAGNETIC SHUTTLING

- COLLECTING TRAY / TRANSPORTATION PALLET

- PRE-MAG

- K-DRUM

How the PAC-MAG Works

More Magnetic Separator Solutions

The GT-MAG